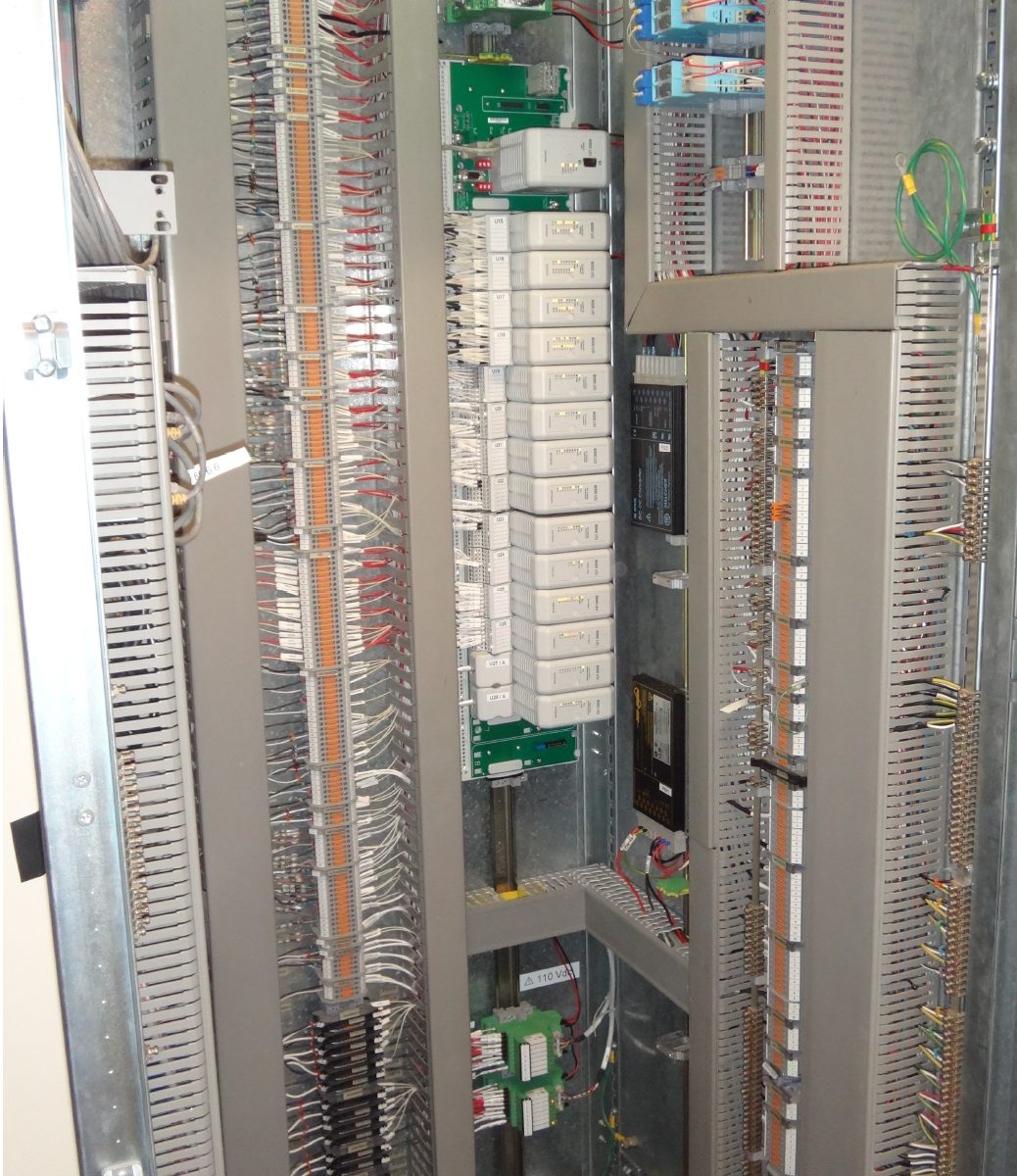

Panel Engineering / Cabinet Engineering

After the system scope is established either based on a customer request or I/O list compiled during a site survey, a preliminary hardware selection is made to match the system I/O. From this point onward the panel needs to be fully engineered to meet the site specific requirements. This includes :

- Preparing the I/O list based on redundancy requirements.

- Selection and interfacing of included safety systems (SIL).

- Selection of control computer or PLC hardware (CPU redundancy, I/O link redundancy, etc.).

- Sizing of power supplies and redundancy.

- Sizing of fuses and breakers.

- Barriers, isolators for ATEX zoning.

- Physical panel lay-out to optimize EMC immunity and site access options (panel size, doors, cable entry points, marshalling, door mounted panels, etc.).

- Wiring diagrams.

- System manuals for installation and operation of the system.

Cabinets can be engineered according to either CE/EMC or UL standards, but generally the CE/EMC standard is followed. The cabinets are engineered in-house and construction is done by certified cabinet builders. After internal testing at completion of the panel, the panel FAT is a witness point prior to shipment to site for installation.