Consultancy

The term consultancy covers two aspects of supporting a customer. The first is to assist a customer during the process of determining and evaluating project requirements for a typical engineering project. The second part of consultancy are more generic engineering know-how related studies.

Project specific – Scope and site

Most of the issues encountered at site during the commissioning and commercial operation are related to the lack of system integration. These issues can range from system interfacing to operational performance limitations. These issues can be easily avoided when a clear specification is created at the start of a project. Typical areas where we are able to assist are :

- Identifying system functional requirements

- Determine system scope

- Write technical specification document for tender

- Technical evaluation of proposals

- Attendance of project meetings

In the event that the project is related to a system upgrade or retrofit, it is likely that a site survey is required. During a site survey a document will be created to reflect the current site situation. Information from the site survey will include:

- Current system performance

- System components to retrofit

- Site physical requirements (ambient conditions, available space and access)

- Instrumentation, actuation, valves, etc.

- Operator experience with old installation

Based on the above, the project scope should be narrowed down to prepare for the regular engineering processes.

Engineering questions

In addition to the project related requests we received, we also are contacted for other inquiries. Usually these are answered in a form of a findings report for further information and processing by the customer.

-

SIL / HAZOP study reviews. With modern system designs, usually there is a form of SIL certification present. The bottleneck is that for a given system the required assessment can be challenging if the equipment is not fully understood.

-

Study to prepare for life extension of a site. Based on available spare parts an assessment was requested what the best options would be to keep the unit in operation or upgrade at a minimum budget.

-

Fuel valve sizing and selection. How is the gas composition affecting the gas turbine cycle parameters and will the gas valve be required to change.

-

Witness and performance pass-off test attendance for various equipment.

- Control panels and related protection devices

- Software testing and FATs

- Gas turbines, boilers, combined cycles.

-

Prepare HRSG cable tray routing for power and instrumentation cables. Cable connection lists. Equipment connection hook-ups.

-

Prepare HRSG light plan based on 3D model

- Emergency lighting

- Normal lighting

-

Assess fauling characteristics to determine the optimal air filter configuration for a given operating profile.

-

Review 3rd-party software designs for gas turbine fuel control cores.

-

Represent customer as owners engineer for multiple units, equipment inspections during installation and commissioning at site by OEM.

-

Investigate load sharing and grid connection options when introducing a power interconnect between two chemical plants. How to maintain sufficient spinning reserves while optimizing overall fuel consumption.

-

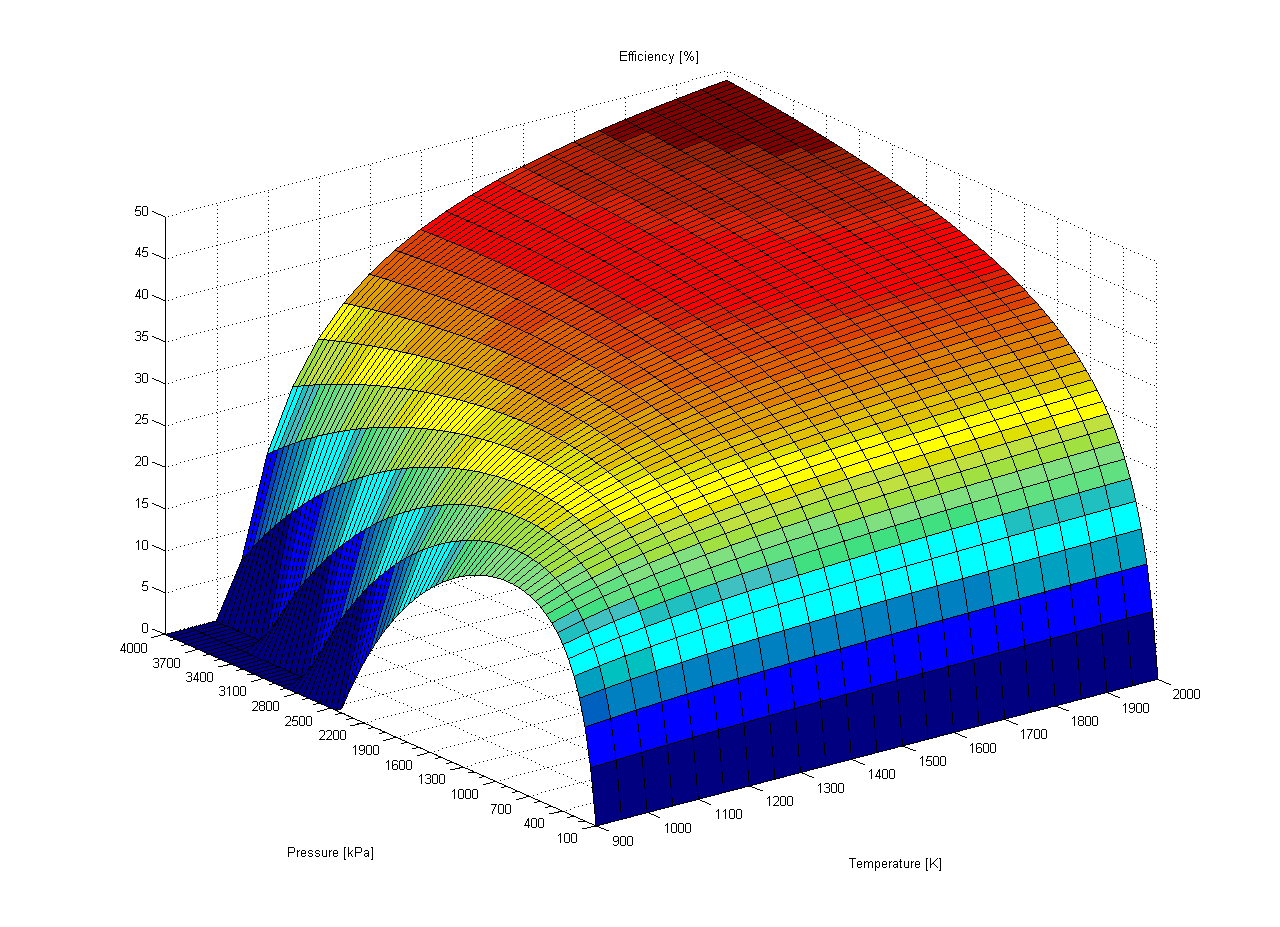

Determine optimum steam admission and extraction pressures for steam turbine relocation to optimize HRSG efficiency.

-

Investigate options to black-start a fluidized bed system using a kinetic energy storage system in combination with a small diesel generator set.